6 | PREPARATION OF THE BASE

murogeopietra can be applied directly to untreated rough walls, on any kind of mortar with good mechanical characteristics and on appropriately secured insulation. Special base preparation procedures must however be carried out for wood, metal, plasterboard, reinforced concrete, foam concrete, weak plasters, and painted or treated surfaces before installing the wall covering.

These instructions are the result of numerous tests carried out and experience gained on site over the last 20 years.

Even though this base is suitable for anchoring purposes, direct installation on brick will not guarantee protection against rain, which could saturate the wall and lead to serious dampness inside. The Geopietra® covering should not be viewed as a waterproofing layer and in the case of a dry installation technique it may even lengthen the time taken for water to drain.

Another issue with this base is its ability for absorption, which could soak up the adhesive when fitting the covering.

To avoid these issues, in the presence of vertical walls with upper covering, apply a coat of waterproof plaster with suitable mechanical characteristics to the thickness recommended by the manufacturer (see also sections 6.5 and 6.6).

To make the wall uniform and improve resistance against water, apply a minimum 5-mm thick reinforced layer using the adhesive recommended by the foam concrete manufacturer, with high-strength fibreglass mesh embedded, such as Georete. Drill holes and secure the assembly using special wall plugs (cat. E) positioned in a grid no larger than 50x50 cm (i.e. minimum 4 wall plugs/m²) ensuring that the plug heads are covered with the adhesive to prevent water infiltrations. Only install the covering once this layer is dry.

This is one of the most stable bases but it is also one of the most difficult to work with. Consider the following in particular:

• Only install on reinforced walls that have been left to set for at least 3 weeks.

• If release agents have been used to remove formwork, sand the wall or wash it with diluted acid (rinsing well after completing the operation);

• In the presence of dust or moss wash with water at high pressure;

• After washing the base, ensure there is no film of water when applying the adhesive, given its lack of absorbency;

• Note the temperature of the base as reinforced concrete holds heat and could overheat the adhesive in summer (or freeze it in winter);

• In the case of retaining walls there must be suitable waterproofing on the side facing towards the soil, otherwise water infiltrations could cause detachment or the appearance of chronic efflorescence. To prevent this issue it is advisable to make holes for water drainage (and include the wall covering), or put up false asbestos cement walls to separate the stone from the wall. There is no waterproofing solution on the visible side (facing away from the soil) that will provide long-lasting protection (see section 3).

• A double coat must always be applied to reinforced concrete otherwise detachment issues will eventually arise.

• Prefabricated reinforced concrete structure: it should be considered that prefabricated structures undergo considerable movement. External cladding reduces this phenomenon significantly by stabilising temperature and internal humidity. Any sort of covering on it is no longer affected by structural movement, given that the cladding insulation panel is an excellent shock absorber due to its elasticity. Always fit the covering in accordance with structural joints, reproducing them on the surface. (see section 10.3)

Apply a layer of tar to iron bases followed by a 2-mm galvanised electro-welded metal mesh (5x5 cm mesh) secured to the loadbearing structure with screws/staples at a maximum distance of 20 cm from each other, turning the mesh back on itself at corners and overlapping joints by at least 10 cm. Keep the mesh a few millimetres away from the base so that the next application of Geocoll® can surround the metal wires completely. Install the wall covering once completely dry.

The heat-insulated plasters on the market have been designed to be breathable and resist the passage of heat but their mechanical strength is only sufficient to support light wall coverings. murogeopietra cannot be applied directly as it weighs considerably more than a standard finish.

To eliminate any risks it is advisable to remove processing dust with water, then attach 160 g/m² of fibreglass mesh embedded in a double layer of Geocoll®, overlapping joints by at least 10 cm. Secure the arrangement using insulation wall plugs of a suitable type, shape and length for the base at a maximum distance of 50 cm from each other (i.e. 4 pieces/m² minimum), and cover the head plate with Geocoll® to prevent water infiltrations.

There are several types of ready-mixed plasters with different mechanical characteristics depending on the composition and type of processing. Each case should be assessed carefully by the installer by testing resistance (cutting with a small metal object) and consulting the product information leaflet. In general plasters which are lime-based only (usually used internally) must be reinforced using mechanical anchoring with Georete (see section 5).

Lime and cement-based plasters could provide good resistance, provided they are only worked with a plastic or wooden straight edge and trowel. However, if a plane (scratch float) is used the wall must be washed and, when the damp film has disappeared, strengthen the surface resistance with a layer of Geocoll® (with a fairly soft paste and possibly inserting 160 g/m² of fibreglass mesh). Install the wall covering once completely dry. If there are any doubts over base resistance it is advisable to carry out a pull-off test.

If the Murogeopietra is to be fitted to walls with no guttering or which are very exposed to bad weather the use of waterproof plaster is recommended.

Take care in the presence of paints as there is no treatment or pitting technique that can ensure the integrity of the wall covering. Two reliable procedures include:

1. The compete removal of the paint down to the stable base. Remove the surface layer completely by sanding or using a stripping machine until a stable base is revealed, wash with water to remove dust and coat the surface with Geocoll®. Install the wall covering only once completely dry.

2. Installation by mechanically anchoring to the base. For mechanical anchoring attach Georete fibreglass mesh embedded in a double application of Geocoll®. Once dry, secure the arrangement using wall plugs of a suitable type, length and shape for the base at a maximum distance of 50 cm from each other. It is advisable to turn the mesh back over on itself at the corners and overlap joints by at least 10 cm. Ensure the next layer of adhesive also covers the heads of all the plugs. Install the wall covering once completely dry.

On the inside it may be quicker to attach a false plasterboard wall mechanically to the base (see instructions in section 6.13). Outside it is advisable to anchor mechanically with Georete (see section 5).

Geopietra® is highly breathable but is not a moisture-removing material, however by using suitable systems and materials it can still be used on areas with rising damp. This depends on the extent of the damage, which should be assessed by the installer:

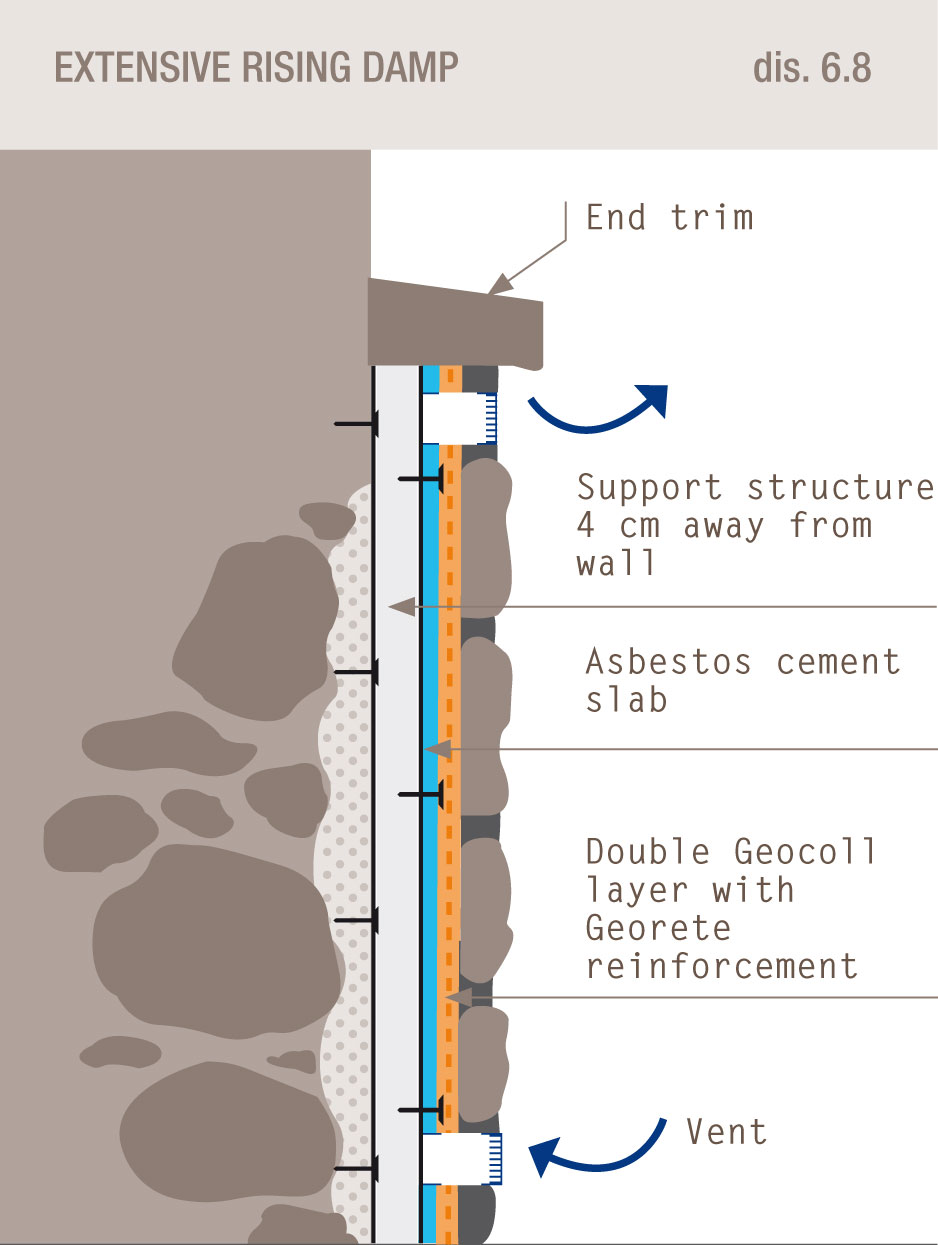

- Extensive softening on the base with plaster clearly coming off: remove down to the base, restore with reputable anti-damp plaster, put up a false wall at least 4 cm away from the supporting wall, with posts and slabs in asbestos cement.Fit the stone to this structure after a double application of Geocoll® reinforced with Georete fiberglass mesh. On external skirting, the covering can be finished off with an upper section or other material depending on preference. It is very important to install vents at the top and bottom to enable adequate air circulation and keep the base dry. (Fig. 6.8).

- Signs of plaster softening: remove any layer that could create a barrier to breathability and remove as much of the plaster around ruined parts as possible. Restore with moisture-removing plaster, which can also be used as an adhesive and grout for the stone itself.

- Small signs of paint flaking off: remove any layer of material that could create a barrier to breathability (e.g. paints or treatments), glue with Geocoll® and grout with GeoBi.

Included among hazardous bases comparable to paints are all surface treatments and deep sealants that have not penetrated properly (with the formation of a surface film).

The use of these products makes testing necessary before proceeding with the installation. Apply the adhesive and carry out a pull-off test once dry. Adhesion is only guaranteed if the base (e.g. plaster) secured to the adhesive comes off along with the stone.

No adhesive can guarantee secure installation in the case of tar overlaps. It is advisable to use Georete fibreglass mesh secured over two thirds of the structure and a third overlapping the sheath. Proceed with mechanical anchoring as outlined in section 5 and apply the Geopietra® covering once completely dry. Any loose sheath will be supported and held by the reinforcement over time.

The characteristic of this base is a high level of absorbency. To avoid problems a waterproof bonding treatment must be carried out using a deep bond coat primer at least 24 hours before installation.

Avoid surface primers or similar which can form a film causing the wall covering to come off. To test the effectiveness of the primer, glue some stone and once dry perform the pull-off test. Adhesion is only guaranteed if the base comes off along with the stone.

A good alternative to the primer consists of etching into the base, soaking it well with water and installing the covering, which must never be carried out in the presence of a film of water. To avoid any treatment it is possible to use one of the many adhesives on the market especially for gypsum and plasterboard bases.

The Geopietra covering shrinks when the adhesive and finishing materials are drying, which normal brickwork bases can tolerate, however plasterboard may not be able to withstand the stress and cracks could form on the covering. It is difficult to stipulate a rule for all situations, as the behaviour parameters vary depending on surrounding temperature, amount of water used to grout joints, type of filler used, wall dimensions and how the steel structure has been constructed, etc.

The most significant issues transpire in the following cases:

• Wall dimensions over 5 metres in length.

• Winter installations when drying times are longer.

• Grout with too much water.

• With full and overgrout joints.

A possible solution is to even out the base with a double application of Geocoll and Georete reinforcement (it is advisable to reduce the absorption strength in the case of normal sheeting - see section 6.11). When the wall is more than 5 metres long, split it up using a false column or something else which acts as a joint. Shorten drying times by heating the area where the work is implemented (15-20 °C). In the case of plasterboard walls that have already been painted, it is possible and practical to secure another sheet to the underlying structure, in order to create a secure base.

Using a magnet identify the position of the columns and screw on damp-proof sheets, staggering the joints with respect to the previous joints and obtaining a perfect surface for installing the Geopietra, without even grouting the new joints.

Alternatively proceed with a mechanical anchoring technique (see section 5).

Material used as disposable formwork, where fixing to the structure involves the concrete itself and the base does not have fixed dimensional stability. The absorption of water could lead to considerable expansion, resulting in complete detachment from the base after occurring several times. Proceed by checking the anchoring of the panels to the base and fit mechanical plugs if necessary. Make the surface uniform with a double application of Geocoll® adhesive and insert Georete fibreglass mesh, folding it back on itself at the corners and overlapping joints by at least 10 cm.

With wood fibre blocks implement a double application of Geocoll® adhesive, inserting 160 g/m2 fibreglass mesh and folding it back on itself at the corners and overlapping joints by at least 10 cm.

With particularly loose bases or bases with significant movement, a false wall with a galvanised steel structure can be erected (or wood to avoid electromagnetic fields), covered in plasterboard (internal) or asbestos cement (external).

(See specific installation procedures).

One of murogeopietra’s main features is good permeability which enables walls to breathe and makes homes comfortable, therefore the material has good surface absorbency characteristics. It is not an issue for it to be in contact with water but, as with natural stone, it is subjected to the harshness of chlorine or salts in swimming pools, and chemical products and detergents used for cleaning.

A) In showers, bathtubs, swimming pools and similar places, where hygiene is of the utmost importance and the impermeability of coverings is crucial, Geopietra® manufactured stone veneer is not very practical and therefore not recommended. If installation is desired regardless proceed as follows:

1. Waterproof the base using a suitable cement-based product (osmotic cement), reinforced with 160 g/m2 of fibreglass mesh.

2. Glue the stone with special adhesive for use under water (adhesive for swimming pools) and then grout.

3. Wait until the walls are completely dry (6-8 weeks in a heated environment) and apply a protective glaze treatment. The treatment should create a surface film that does not permit absorption. It is advisable to use models with surfaces that do not have too many indentations, avoiding dry-stack installation-cleaning could be problematic and impractical, resulting in the accumulation of dirt and germs in the stone recesses.

B) In areas where murogeopietra is installed in the vicinity of swimming pools and is only occasionally affected by sprays of salt water or chlorine, wait until the walls are completely dry (6-8 weeks in a heated environment) and apply a water-repellent treatment. Opt for a water-based protective treatment, such as a siloxane treatment, which does not affect the breathability of the stone (open pore) or change its appearance.

C) In sauna rooms or Turkish baths Geopietra® manufactured stone veneer is only dampened by steam, therefore it is not subjected to harsh conditions due to chemicals. The stone acts as a steam drum by regulating the steam, therefore it is advisable not to proceed with any type of treatment, enabling the material to breath as much as possible. Apply the wall covering following steps 1 and 2 in section A (showers, bathtubs and swimming pools) and clean regularly (see section 17). To reduce any absorption an open-pore siloxane treatment can still be applied once the wall is completely dry.

Covering fireplaces, chimney breasts and stove areas should not pose any problems, the only precaution is to ascertain whether or not the surface temperature exceeds 180°C, which is the maximum limit that can be tolerated by the adhesive and mortar, therefore beware of any thermal expansion in the loadbearing structure. The installation of murogeopietra within barbecue areas is not recommended.

There may be several reasons as to why a wall has been waterproofed, and in this situation mechanical anchoring by making holes directly in the waterproofing layer cannot be implemented to support a covering. There are waterproofing materials such as bentonite cements, which the adhesive grips without any issues. Obviously the base waterproofing must be guaranteed by the supplier and installer of the waterproofing material, as it is this which has to withstand stress due to the weight and thermal expansion of the covering.

It is difficult to find a solution for other waterproofing materials, such as bitumen sheets, as no adhesive can maintain suitable grip over time. In the case of small waterproofed surfaces with a maximum height of 40-50 cm on the bottom of walls with a secure base, they can be overlapped with fibreglass Georete®, covering the equivalent length of the wall at least, to allow for the mechanical fasteners secured to the structure. Set this in a double application of Geocoll and wait till it is completely dry before fitting the covering (see section 5).

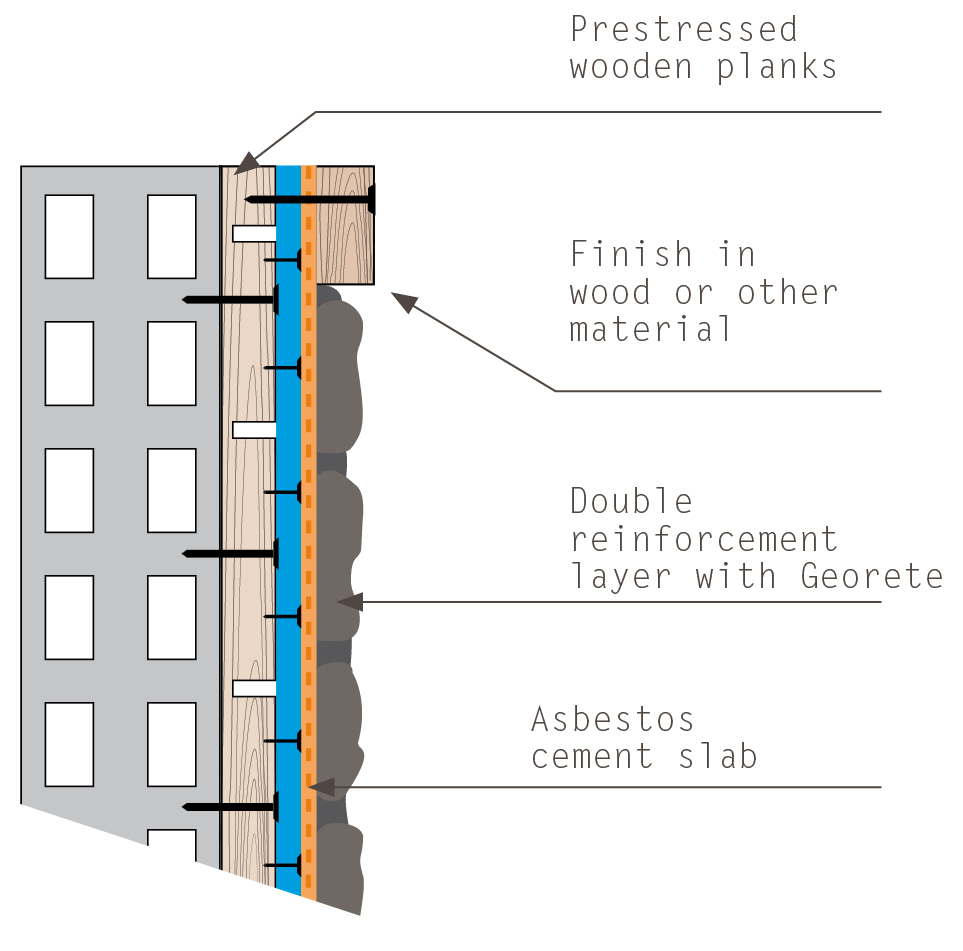

A steel or aluminium criss-cross structure secured to the base with plugs is normally used to ensure free movement in all directions. Asbestos cement sheets are secured to the structure using self-drilling screws positioned 20 cm apart, which are guaranteed by the supplier to support a covering of approximately 70 kg/m2.

Feasible surfaces must have maximum dimensions, dictated by the sheet supplier, that consider movement due to the thermal expansion of the materials used. As a precaution it is advisable to apply a double layer of Geocoll on these surfaces to further mitigate movement and prevent accidental breakage points that are difficult to detect in the design stage. Ventilation holes are necessary at the top and bottom of the wall and should also be observed when installing the Geopietra®.

Issues transpired on site for the following reasons:

• Asbestos cement sheets secured to simple vertical or horizontal columns being subjected to movements in the underlying structure.

• The aforementioned problem is exacerbated with the use of wood strips in the structure, which move significantly with changes in temperature (see photo).

In the pictures | Installation on ventilated wall you can note the split created by the strong tensions due to a wrong substructure made of wooden posts to which cement sheets were fixed.

If these have to be used, it is advisable to counteract this by making cuts in the wood strips perpendicular to the grain at a distance of 1 metre using a saw (see diagram).

Wood typically moves continually and manufactured stone veneer must be installed on a perfectly stable base or a base with expansion characteristics similar to the manufactured stone veneer, making compatibility difficult. The recommended solution consists of putting the Murogeopietra on a separate surface to the wooden loadbearing surface, such that it is not subjected to the movements.

1. False wall in asbestos cement on a criss-cross structure.

2. External thermal insulation.

The first is described in section 6.19 and can be used in special cases with bases that are very loose or similar.

The second is more highly-recommended for obvious thermal reasons, and especially because it acts as an excellent shock absorber for any movements in the underlying structure, with the exception of expansion joints, which must always be on the surface. Gluing insulation onto wood can create adhesion issues and many manufacturers recommend secure plugging techniques.

The procedure used in our guaranteed solution is outlined below; always consult the insulation manufacturer.

A loadbearing wooden structure must have a protective wooden structure on the whole outer surface (diagonal covering: 3-S, OSB panels or similar) to enable adhesive to be applied to the entire surface, in addition to suitable mechanical anchoring. In principle, the entire surface of the insulation should be covered with a suitable adhesive and secured immediately with 2 wall plugs.

The GEOPIETRA covering must then be secured mechanically using self-threading screws, without requiring holes to be drilled beforehand using an 8-mm drill. At joints between massive brickwork (e.g. cellar) and wood there are structural expansion joints that must be observed in the insulation (sealing tape, skirting profile or other solutions). Alternatively, anti-damp plasterboard sheets can be screwed to the loadbearing structure onto which the insulation can be glued.

The photograph | shows the crack caused by a lack of waterproofing on the wood base. The penetrating water, or even just the dampness, has caused the materials to expand and their movement has split the stone at the corners.

The OSB panels type, fitted on an appropriate underlying structure, such as a lattice structure of small beams, are not subjected to movements and a covering can be fitted after preparing the panels as follows: position a micro-perforated steam-permeable membrane on the wooden structure and then a 2-mm galvanised wire electro-welded metal mesh (5x5 cm mesh) secured to the loadbearing structure with screws/staples at a maximum distance of 20 cm from each other, turning the mesh back on itself at the corners and overlapping joints by at least 10 cm. Keep the mesh a few millimetres away from the base so that the next layer of Geocoll® can surround the metal wires completely. Install the murogeopietra once completely dry.

The photograph | shows cracks at the corners at the level of the loadbearing slab, where an OSB panel was screwed directly onto the horizontal laminated beam. The beam expanded and triggered sufficient forces to break the end section of the glued stone.

It should be considered that prefabricated structures undergo considerable movement in general. External cladding reduces this phenomenon significantly by stabilising temperature and internal humidity. Any sort of covering on it is no longer affected by structural movement, given that the cladding insulation panel is an excellent shock absorber with its elasticity. Structural expansion joints must be observed when installing the covering. (see section 10.3)

To cover iron and wooden pillars and prevent the expansion of materials cracking the covering, it is advisable to box the structure in with plasterboard and asbestos cement slabs, leaving the arrangement slightly detached. If anti-damp plasterboard sheets are used also apply EPS insulation. In both cases it will be necessary to wrap Georete fibreglass mesh embedded in a double layer of Geocoll® adhesive around the structure.

It is advisable to bring the pillars to the minimum external dimensions of 25x25 cm before covering them with the Geopietra® manufactured stone veneer.